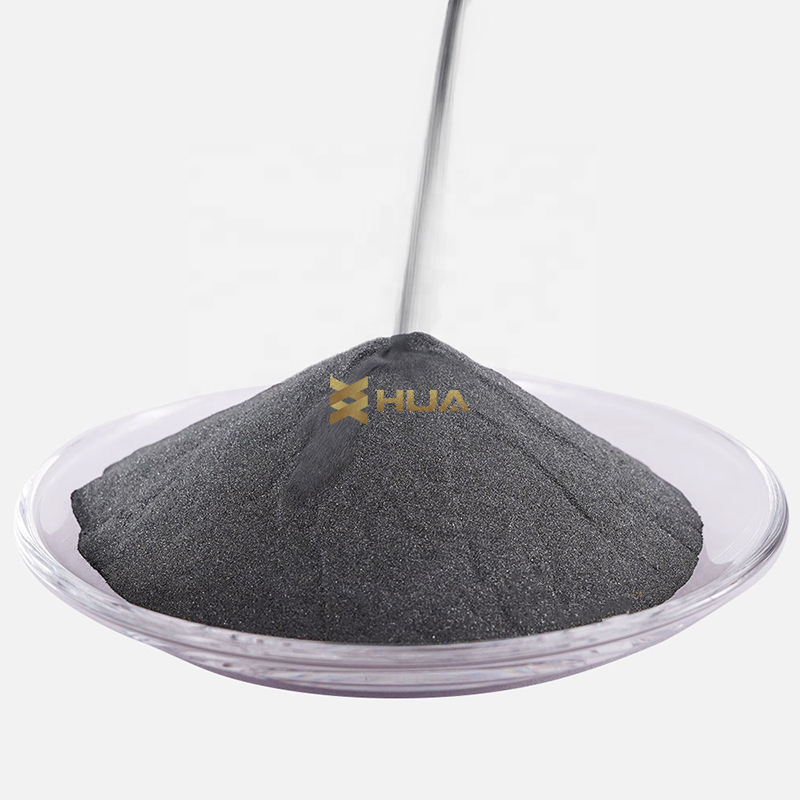

Aditif Manufaktur Stainless Steel Powder 316l Powder kanggo Printing 3d

Deskripsi Produk

Wêdakakêna stainless steel digawe kanthi proses atomisasi banyu lan nduweni resistensi korosi lan daya tahan sing apik.Wêdakakêna stainless steel nduweni macem-macem kegunaan industri.

Nyedhiyakake macem-macem bubuk logam stainless steel kanthi ukuran partikel sing beda.

Miturut panggunaan

1. Panas Isostatic Pressing

2. Metal Injection Molding

3.3D printing

4. Penyemprotan termal

Miturut proses produksi

1. Atomisasi banyu

2.Atomisasi gabungan gas banyu

3. Atomisasi gas

4. Atomisasi vakum

Rincian spesifikasi

| Komposisi bubuk baja stainess% | |||||||||

| sasmita | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0,08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0,07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Aplikasi

Wêdakakêna stainless steel bisa digunakake kanggo nyemprotake termal, metalurgi bubuk, sintering press metalurgi bubuk (PM), saringan sintering cetakan injeksi (MIM), lsp, isi oksigen atomisasi banyu.<4000PPM, atomisasi gas<1000PPM.

Kauntungan saka bubuk baja tahan karat HUARUI

●Komponèn bubuk malah, kurang impurities

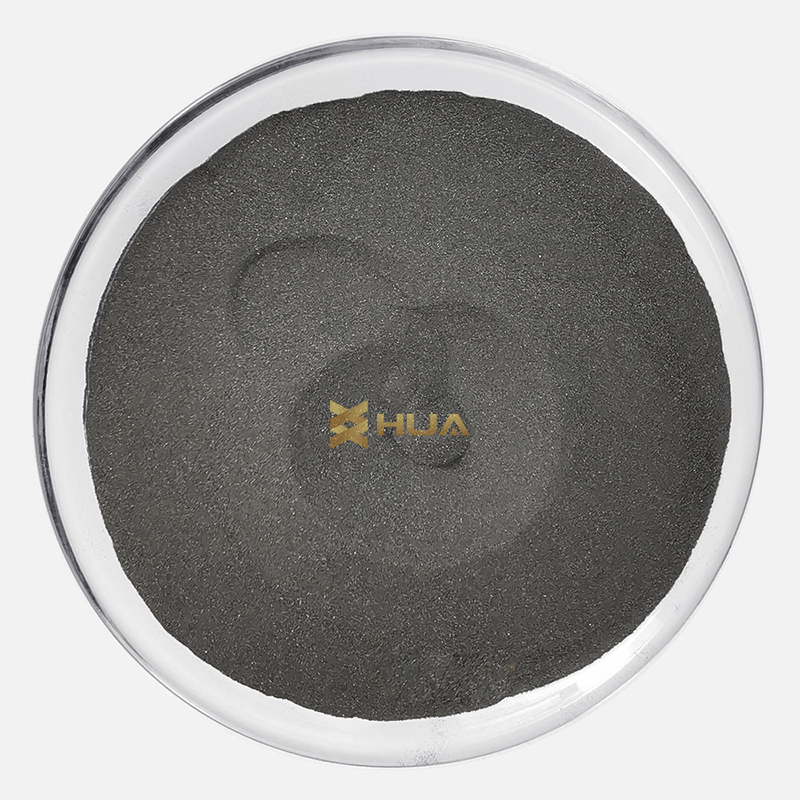

●Sphericity dhuwur

●Kandhut oksigen kurang

●Flowability apik

● Kapadhetan ngeculke dhuwur, Kapadhetan tunyuk dhuwur

●Kurang bubuk kothong, kurang bubuk satelit

Sistem kontrol kualitas

1.Huarui nduweni sistem manajemen kualitas sing ketat.Kita nyoba produk kita dhisik sawise rampung produksi, lan kita nyoba maneh sadurunge saben pangiriman, malah sampel.Lan yen sampeyan perlu, kita seneng nampa pihak katelu kanggo nyoba.Mesthi yen sampeyan seneng, kita bisa nyedhiyani sampel kanggo sampeyan kanggo nyoba.

Kualitas produk 2.Our dijamin dening Sichuan Metallurgical Institute lan Guangzhou Institut Riset Metal.Kerjasama jangka panjang karo dheweke bisa ngirit akeh wektu tes kanggo para pelanggan.