IN625 Nikel Base Alloy Powder Inconel 625 Powder

Deskripsi Produk

Huarui suhu dhuwur paduan basis nikel IN625 bubuk punika bubuk optimized, utamané cocok kanggo teknologi mbentuk SLM, kalebu EOS Selective Laser Melting Equipment (EOSINT M Series), Concept Laser Melting Equipment, Renishaw Laser Melting Equipment, American 3D Systems Laser Melting Equipment, lan institut lan institut riset domestik.

Liwat distribusi ukuran partikel sing beda-beda, bisa uga dipérang dadi bubuk injeksi, bubuk kelongsong laser, bubuk uyuh, bubuk penekan isostatik panas lan liya-liyane.

Spesifikasi

| Komposisi Kimia(%) saka Inconel 625 Powder | ||||||

| Cr | Co | Al | Mo | Mn | Ti | Nb |

| 20-23 | ≤1.0 | ≤0.4 | 8.0-10 | ≤0.5 | ≤0.4 | 3.15-4.15 |

| Fe | C | Si | P | S | O | Ni |

| ≤0.5 | ≤0.1 | ≤0.5 | ≤0,015 | ≤0.15 | ≤0.02 | Bal |

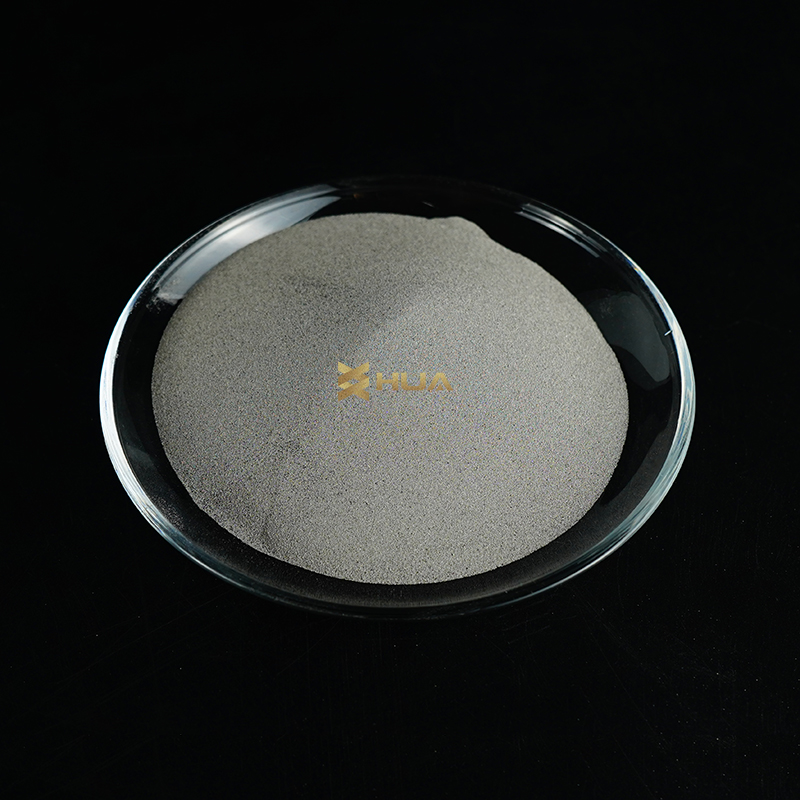

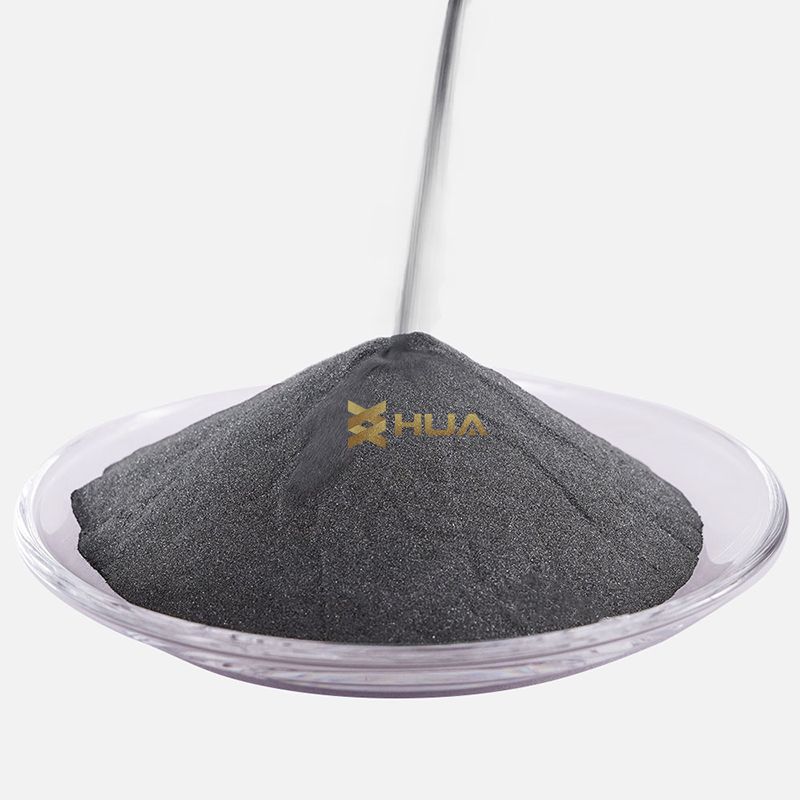

| Kapadhetan katon: 4.50g/cm3 | Warna: grey | Wujud: bunder | ||||

| Ukuran partikel | 15-53 mikron;45-105 mikron;45-150 mikron | |||||

| Inconel 625 Powder Properties | ||||||

| Ukuran Range | 0~25um | 0~45um | 15~45um | 45~105um | 75~180um | |

| Morfologi | Bunder | Bunder | Bunder | Bunder | Bunder | |

| Distribusi Ukuran Partikel | D10: 6um | D10: 9 | D10: 14um | D10: 53um | D10: 78um | |

| D50:16um | D50: 28um | D50: 35um | D50: 69um | D50: 120um | ||

| D90: 23um | D90: 39um | D90: 45um | D90: 95um | D90: 165um | ||

| Kemampuan aliran | N/A | ≤30S | ≤28S | ≤16S | ≤18S | |

| Kapadhetan sing katon | 4,2 g/cm3 | 4,5 g/cm3 | 4,4 g/cm3 | 4,5 g/cm3 | 4,4 g/cm3 | |

| Kandungan oksigen (wt%) | O: 0.06~0.018wt%, standar ASTM: ≤0.02 wt% | |||||

| Pencetakan 3D Gas Atomized Inconel 625 Powder kanthi rega paling apik | ||||||

| (oksigen kurang, sphericity dhuwur lan fluidity apik) | ||||||

Aplikasi

1. HVOF

2. Lapisan plasma

3. Printing 3D / manufaktur aditif

4. welding welding

5. ngecor injeksi logam

6. isostatik panas

Produk sing gegandhengan

Kita uga nyuplai bubuk Inconel 718, bubuk NiCr, bubuk NiAl, bubuk Ni20-Ni65, welcome to inquiry!