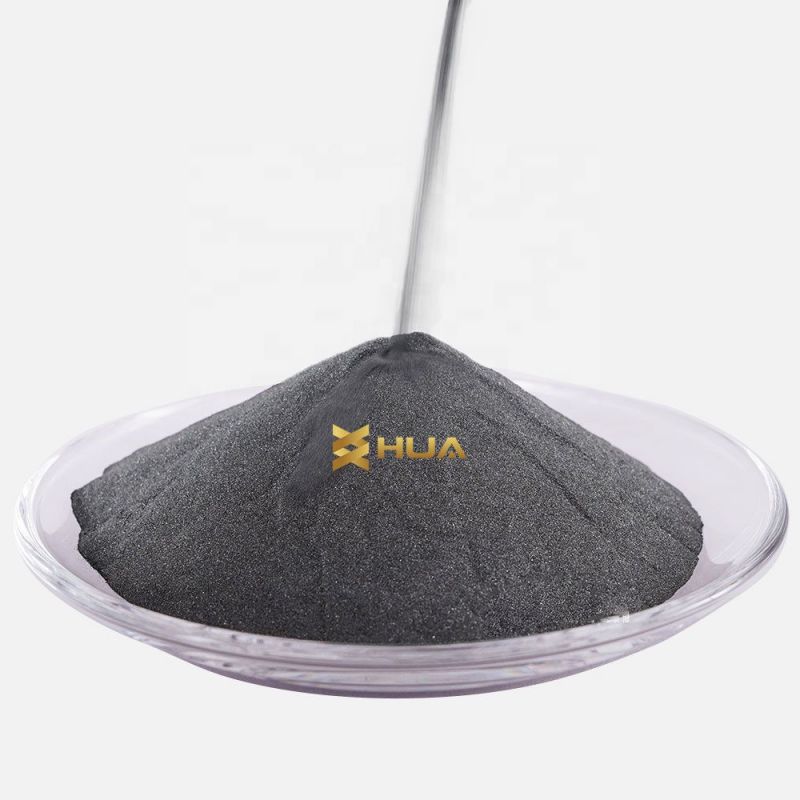

Paduan logam bubuk titanium ti6al4v bubuk kanggo percetakan 3d

Deskripsi Produk

Wêdakakêna Ti6Al4V diarani TC4, minangka paduan titanium α-β kanthi rasio kekuatan-kanggo-bobot sing dhuwur lan tahan korosi sing apik.Iku salah siji saka wesi titanium paling umum digunakake lan digunakake digunakake ing Kapadhetan kurang lan resistance karat banget perlu kanggo industri aerospace kuwi lan aplikasi biomechanical (implants lan prostheses).Ti6Al4V umume dianggep minangka "basa" saka industri titanium. amarga adoh saka alloy titanium sing paling akeh digunakake, luwih saka 50% saka jumlah total titanium.

TC4 titanium alloy wis resistance karat banget.Wis seri kaluwihan kayata Kapadhetan kurang, kekuatan tartamtu dhuwur, kateguhan apik, weldability apik lan ing.Wis digunakake ing aerospace, petrokimia, galangan kapal, mobil, farmasi lan industri liyane.

Rincian spesifikasi

| Komposisi bubuk titanium nitrida | |||

| Item | TiN-1 | TiN-2 | TiN-3 |

| Kemurnian | > 99.0 | > 99.5 | >99.9 |

| N | 20.5 | > 21.5 | 17.5 |

| C | <0.1 | <0.1 | 0.09 |

| O | <0.8 | <0.5 | 0.3 |

| Fe | 0.35 | <0.2 | 0.25 |

| Kapadhetan | 5,4 g/cm3 | 5,4 g/cm3 | 5,4 g/cm3 |

| ukuran | <1 mikron 1-3 mikron | ||

| 3-5 mikron 45 mikron | |||

| expansion termal | (10-6K-1): 9.4 bubuk peteng / kuning | ||

Spesifikasi

| Titanium aluminium alloy (TC4) bubuk Properties | |||||

| Ukuran Range | 0-25um | 0-45um | 15-45um | 45-105um | 75-180um |

| Morfologi | Bunder | Bunder | Bunder | Bunder | Bunder |

| PSD-D10 | 7um | 15um | 20um | 53um | 80um |

| PSD-D50 | 15um | 34um | 35um | 72um | 125um |

| PSD-D90 | 24um | 48um | 50um | 105um | 200um |

| Kemampuan aliran | N/A | ≤120S | ≤50S | ≤25S | 23S |

| Kapadhetan sing katon | 2,10 g/cm3 | 2,55 g/cm3 | 2,53 g/cm3 | 2,56g/cm3 | 2,80 g/cm3 |

| Kandungan oksigen (wt%) | O: 0.07-0.11wt%, standar ASTM: ≤0.13wt% | ||||

Kita uga nawakake layanan khusus

Welcom mbutuhake COA & sampel gratis kanggo Tes

SEM

| Titanium aluminium alloy (TC4) bubuk Unsur utama: | ||

| Al | V | Ti |

| 5.50-6.75 | 3.50-4.50 | Bal |

Aplikasi

1. produksi tambahan sinar laser / elektron (SLM/EBM).

2. metalurgi bubuk (PM) lan pangolahan liyane.

3. macem-macem jinis printer logam 3D, kalebu Renishaw, Renishaw, Jerman EOS (seri EOSINT M), Konsep Laser, sistem 3D lan peralatan leleh laser liyane.

4. Pabrik bagean aerospace, Aeroengine Blades lan bagean liya saka karya ndandani.

5. piranti medis.